Prior to our current co-engineering and manufacturing activities, West End started as a service company.

In 1947 West End was founded as a service oriented company Over the years, we current co-engineering and manufacturing activities,

Since 1947 West End specialises in urgent repair and maintenance. Repair and maintenance often leads to overhaul and refurbishment activities.

Repair, modification and refurbishment has been for many customers the starting point for their long term relationship with West End.

Manufacturing as a service

In order to be able to perform high class refurbishment activitie, West End continuously invests in new capabilities and technologies. Next to the original repair, dis-assembly and transport services on customer site, West End invests in it’s own all-round workshop. Our workshop, or better called factory, is there for all-round and includes certified welding, CNC milling and surface treatments.

Co-engineering

To provide the service of “as-built drawings” West End founded it’s in-house engineering department in the 1970’s. Changes to product geometry are entered in 3D CAD models and working drawings. These as-built drawings can be used for spare parts in the future. Nowadays, we provide co-engineering as a service for our long-term relationships as the starting point of new to be manufactured tooling or equipment. Our engineering includes 3D models, FEM analyses and 2D manufacturing drawings.

est and Assembly Services.

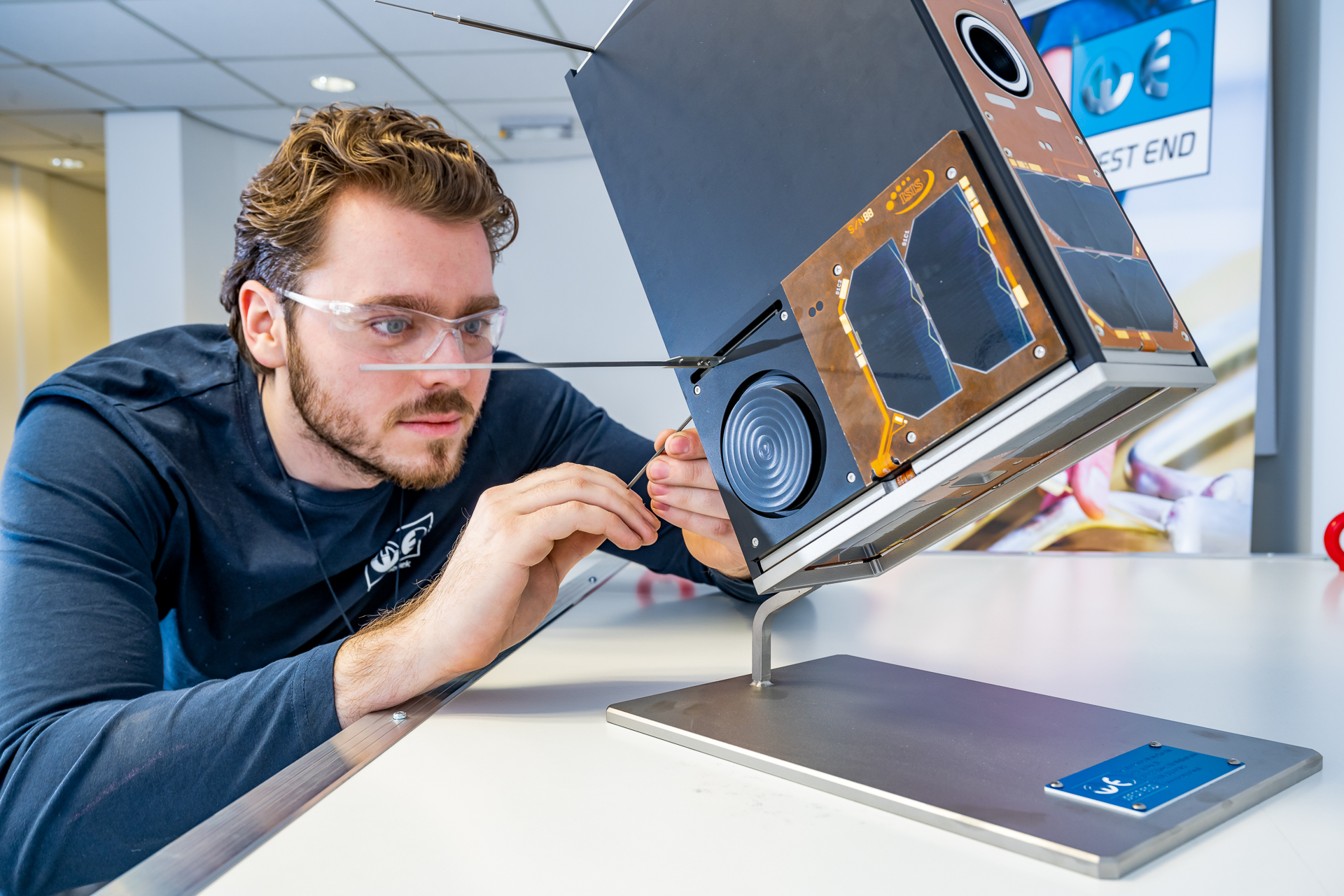

Our goal is to be a one-stop service provider, therefor next to engineering, manufacturing and on-site services, West End also created it’s in-house Test and Assembly team. Examples of testing include fit-checks, load tests, shock tests, pressure or vacuum test and water tightness tests. Next to this, we provide our customers the possibility to perform their test campaign or customer approval acceptance tests in our clean assembly department at West End. Examples of such co-assembly and test campaigns are recently the TMT project and some years ago the testing of the Xenon Space Simulation Lamps prior to it’s delivery to ESA.

On-site services

Field staff

West End has well equipped mobile workshops for installation and maintenance work on site. Our field staff thus support you in installing and commissioning production units.

The field staff are also prepared to remedy malfunctions and perform (regular) maintenance and repairs on our customised solutions on site. The West End field staff can even carry out modifications of parts on site.

Secondment

For our long term partners in Space, Aviation and Industry, our service extends beyond maintenance and installation on site. Our people can be seconded to your company for long term and large projects. Moreover, we are always keen to be close to the customer.

Purchase of additional Equipment and services

West End aims to be an all-round one-stop-shop supplier for it’s partners. Part of this philosophy includes services like purchase, integrate and deliver off-the-shelf components. Next to this we arrange services like special transports of large dimensions.

Metrology

Being a mobile services company part of our metrology equipment can be used at customer sites. West End uses their Faro Prime Arm and Lasertracker not only for their verification of their own installation activities, we also provide technicians with our equipment to support customers with metrology needs.