The MDE-unit is used in civil industry and construction, in the phases leading to building roads or houses.

The MDE-Drive is an installation to detect, deep below ground surfaces, undesired items like explosives from World War II.

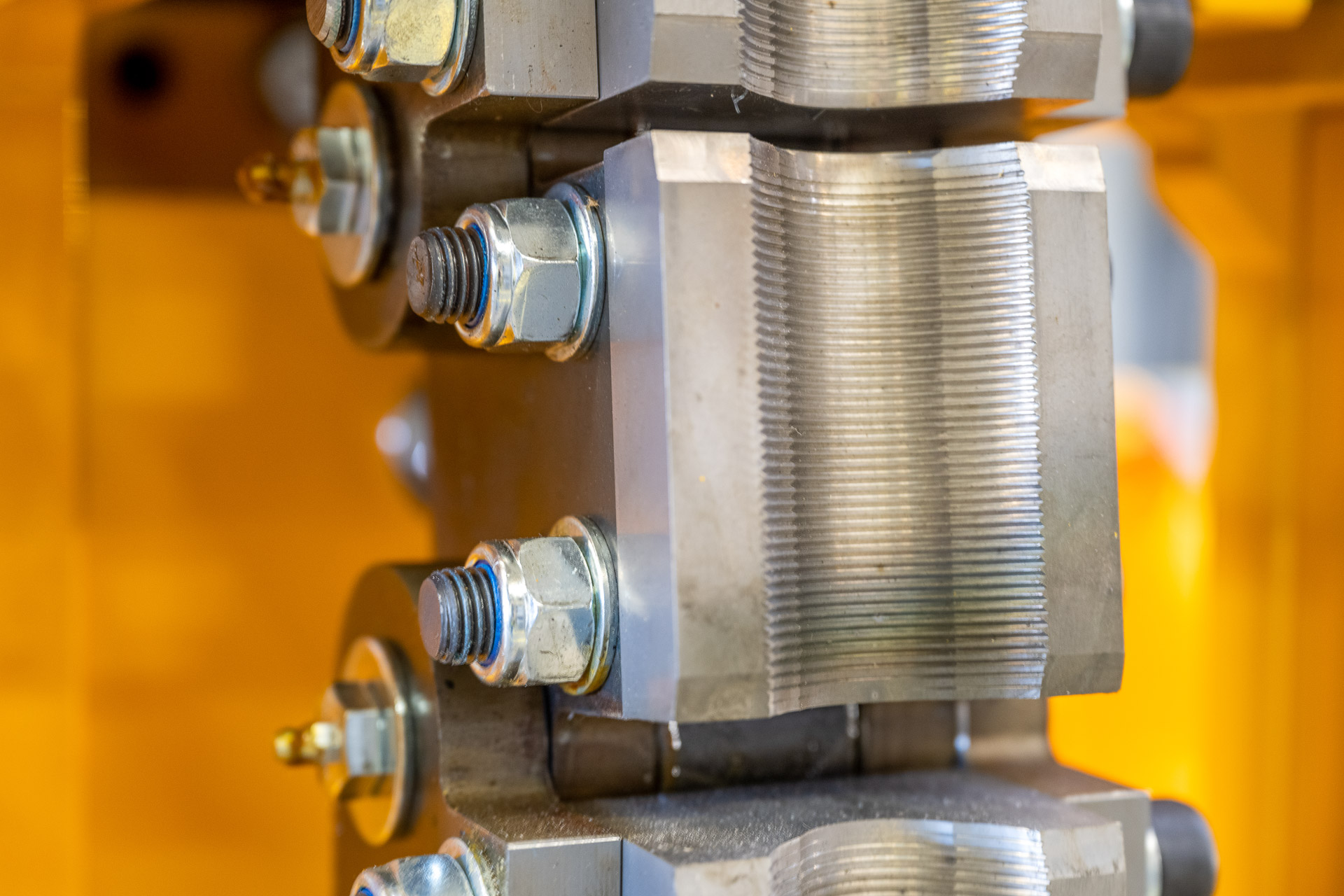

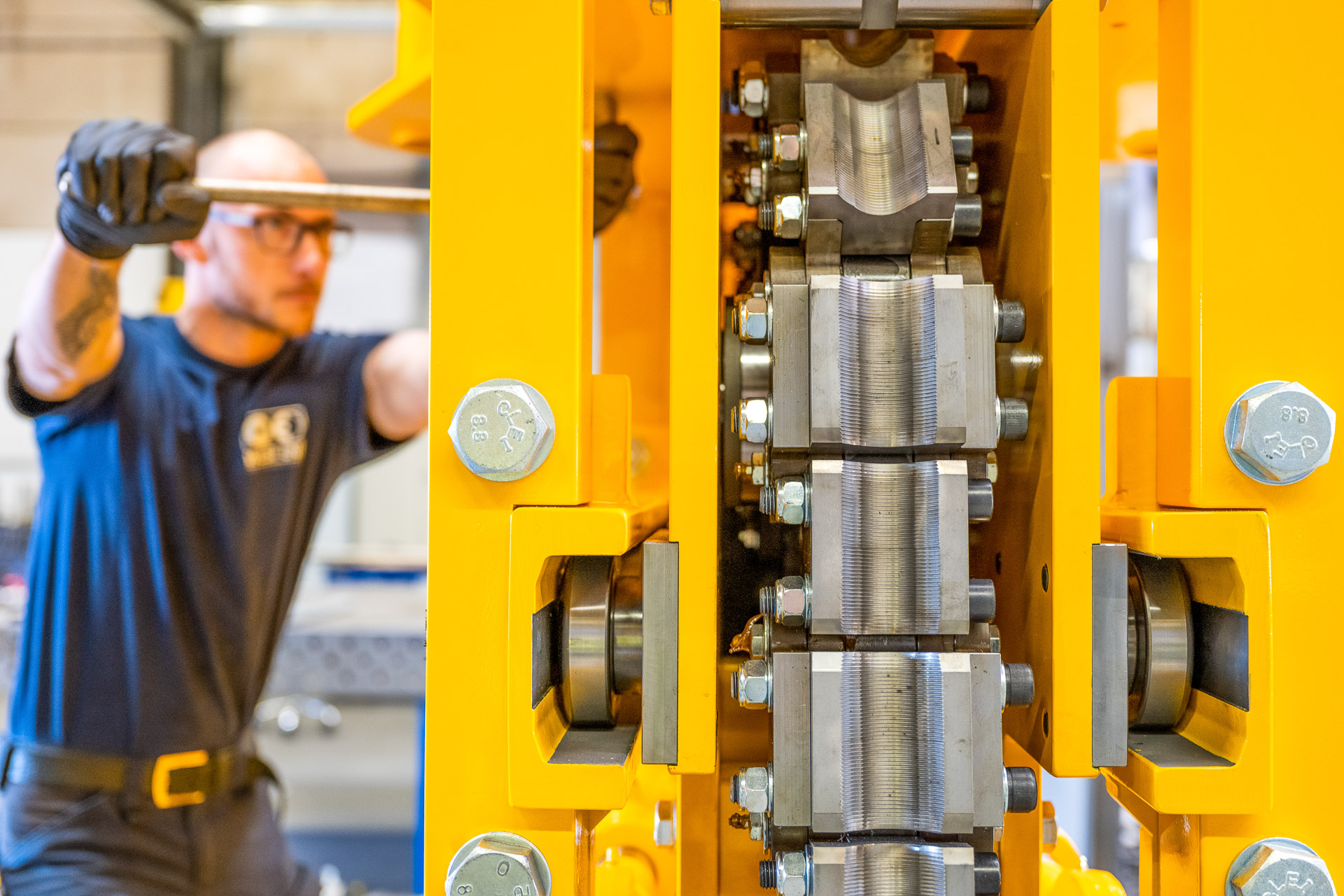

One can describe the MDE-drive as a heavy duty pressure mechanism which can drive a hollow tube deep into the ground. The hollow tube is guided by hardened steel clamps. The tube is guided by a large, but light-weigth de-mountable aluminium, tower-construction above ground level. To avoid magnetic disruption measured by the probes which go deep into the ground, the tubes are often made from stainless steel. The tube is mounted between two hydraulic driven chain belts. These chain belts are made from hardened high strength steel.

The MDE-drive hydraulic system is coupled with the hydraulic system of the caterpillar it is mounted on. One needs a caterpillar to go smoothly through the often rough terrains the MDE-unit is applied.

Technology

In order to manufacture high tolerance, large parts with complex geometries, West End uses modern CNC machinery. We have a Haas UMC-750 5-axis milling machine and a Haas 4-axis GM-2 large milling portal machine (working bed 4.000 x 2.000 mm).

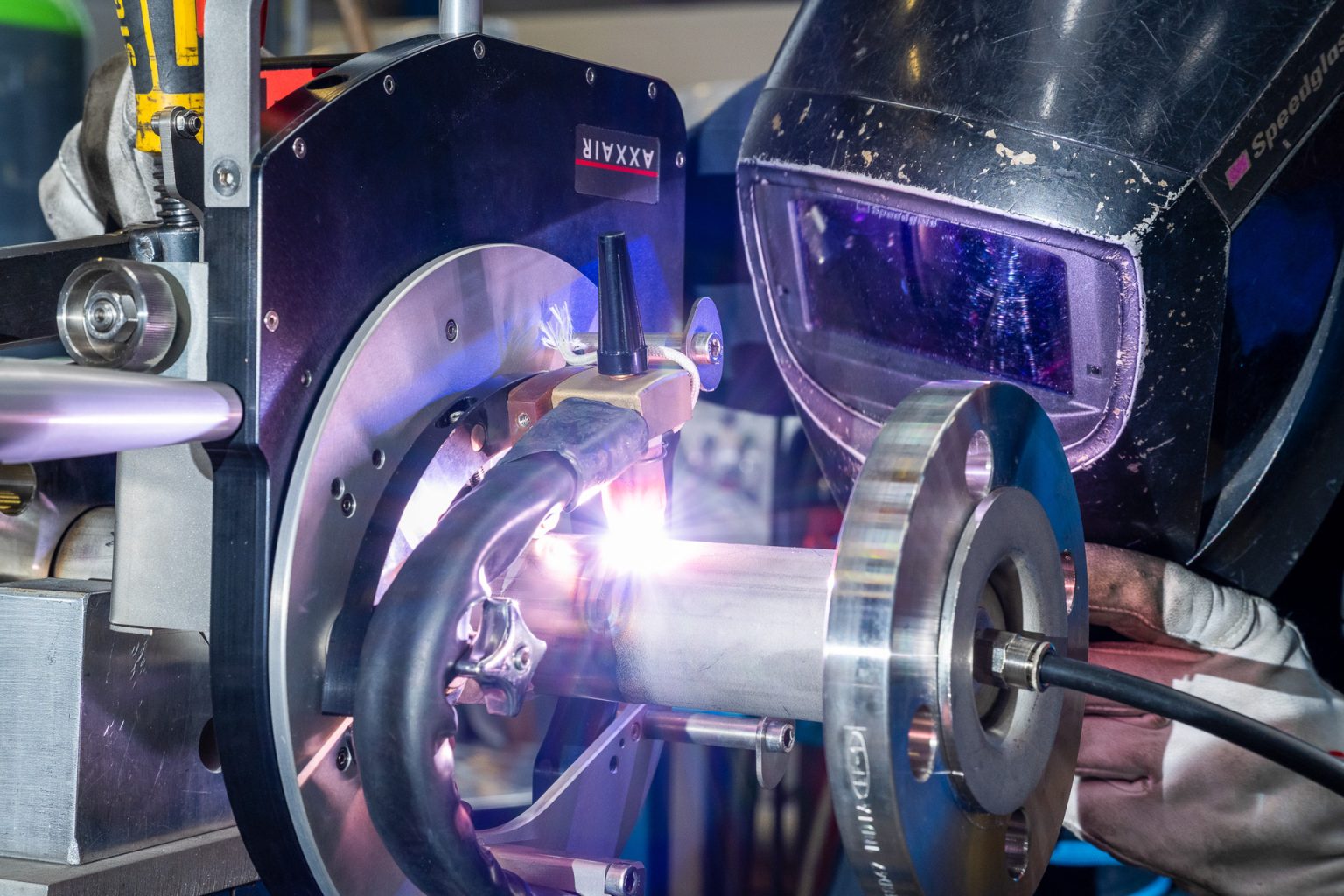

West End has a EN 1090 certified welding department. Aside from aforementioned and the conventional manufacturing techniques, West End has a cleanroom, 3D measuring equipment and testing equipment for pressure, vacuum and cryogenic applications.

Engineering

Built to spec

Using your requirements and specifications as a basis, our engineering department can develop the product design in greater detail and prepare it for manufacture. Our engineers also perform FEM calculations, to check critical construction elements and the final choice of materials. Of course the assembly drawings and detailed drawings are guaranteed for refurbishment, reconstruction and production documentation purposes.

Built to print

West End can also use the 3D models and detailed drawings supplied to switch quickly to producing parts or products. Precisely in accordance with the instructions, specifications and requirements.

Services

Since 1947, West End specialises in maintenance, repair, modification and refurbishment for a broad range of products.

Our factory has an area of 5.500 square meters and houses almost all necessary manufacturing technologies. West End also has an in-house engineering department. Our team of 6 mechanical engineers is specialised in co-engineering. West End has than 75 years’ experience in manufacturing, maintenance and repairs. With that knowledge, our engineers provide detailed designs and manufacturing drawings, aimed at optimal manufacturability of our products.

In order to improve our service levels, West End continuously invests knowledge, certifications, people and new technology. Our engineering services include 3D modeling, FEM analyses and the production and documentation